Understanding the Risks: The Complete Guide to Flexible Hose Connectors and How to Prevent a Sudden Flood

Flexible hose connectors, commonly known as flexi hoses, braided hoses, or stainless steel flex hoses, are everywhere in modern plumbing. These small connectors are used in kitchens, bathrooms, toilets and laundries.

But they’re also one of the top causes of internal water damage when they fail.

Book Your Flexible Hose Connectors Audit & Service Today!

Every home is at risk of water damage from failing flexible hose connectors. Over 22% of insurance water claims are now due to these ticking time bombs.

Schedule your appointment now: Don’t wait for a burst hose to cause chaos. Schedule your expert audit today and keep your home’s plumbing system secure.

Quick answer first (read this in 30 seconds)

Flexible hose connectors (“flexi hoses”) can fail without warning. When they burst, the water damage is brutal, fast, and expensive.

Most failures come from:

❌ Age and wear (especially after 5 years)

❌ Corrosion at the fittings

❌ Heat under sinks and inside cabinets

❌ Chemical exposure (cleaners, salty air)

❌ High water pressure over 500 kPa (a big one, often missed)

Here’s the part people don’t expect.

If water pressure should have been limited and wasn’t, insurance claims can get messy. Not always denied. But questioned, reduced, delayed… and that’s a horrible time to learn policy fine print.

So we don’t just replace hoses. We check pressure, confirm the setup, and give you clear next steps.

If you don’t know your water pressure, check it. Today, not “sometime”.

Start here: Water Pressure Gold Coast: Low vs High Pressure Made Clear

Want certainty? Book a flexi hose safety check. We’ll inspect, pressure test, and document what we find.

Table of Contents

What is a flexible hose connector?

A flexible hose connector is a braided hose with a rubber (or polymer) core.

It usually has crimped ends and threaded fittings.

Flexi hoses are standard in most buildings because they’re:

✅ Quick to install

✅ Easy to route in tight spaces

✅ Handy for fixtures that need movement

But convenience has a cost. They’re wear parts, not “fit and forget” parts.

Why do flexi hoses fail?

Here’s the honest truth. Many hoses look fine right up until they don’t.

The inner core degrades over time. Heat, pressure cycles, and vibration speed that up.

Rule of thumb: treat 5 years as a serious checkpoint. At 10 years, replacement is usually the wise call. Even if it “seems okay”.

The braid can trap moisture. Crimps and ends corrode first, especially in coastal air.

Gold Coast humidity doesn’t help. Neither do wet cabinet floors and slow drips.

Flexi hoses shouldn’t be:

❌Stretched tight

❌Bent sharply

❌Twisted during installation

❌Forced against sharp edges

That stress focuses on the ends. That’s where bursts often begin.

Harsh cleaners that leach from plastic containers under the sink can attack stainless steel braiding and inner rubber cores. So can some sprays, solvents, and pest treatments. Strange but true.

This is the quiet killer.

It doesn’t “look” like a problem until the day it becomes one. Pressure failures show no outward signs and will fail without warning.

High water pressure is the quiet flexi-hose killer

High pressure increases strain on:

⚠️ The rubber core

⚠️ The crimps

⚠️ The tap internals

⚠️ Dishwasher and washing machine solenoids

⚠️ Toilet inlet valves

Pressure also makes tiny leaks worse. A slow weep turns into a blowout.

The key number: 500 kPa

The Building Code of Australia, mandated by the Plumbing and Drainage Act 2018, requires that the outlet pressure should not exceed 500 kPa.

If the incoming water main pressure is higher, a pressure-reducing valve (PRV) is required.

If you’re not sure what your incoming water pressure is, don’t guess. Read our guide: Water Pressure Gold Coast: Low vs High Pressure Made Clear

That page explains:

✅ What “normal” pressure looks like

✅ Why pressure spikes happen

✅ How PRVs work

✅ What symptoms match high pressure (noisy pipes, hammering, frequent leaks)

This matters because pressure is invisible. But the damage is not.

Warning signs you should not ignore

If you see any of these, act now:

✅ Rust staining on hose ends or fittings

✅ Fraying braid or bulges

✅ Wet cabinet base, swollen MDF, musty smells

✅ Water hammer (banging pipes)

✅ Taps and valves are failing often

✅ A flexi hose that feels stiff, cracked, or “crunchy” (yes, that happens)

✅ Hoses that are kinked, twisted, or stretched

✅ A sudden increase in your water usage

✅ A sudden decrease in water pressure

✅ Unusual sounds or vibrations during water usage

Although they seem harmless, corrosion is often hidden beneath the surface. Flexi hoses can corrode from the inside, even when the outer braid appears intact.

Corrosion often forms silently. At Whywait Plumbing, we’ve witnessed the destruction firsthand, and we’re here to help you prevent it.

If you’re unsure, take a photo and call us. You’ll get a straight answer, not a scare campaign.

Chemical Exposure

A flexihose is highly susceptible to chemical exposure from household cleaning agents or poor water quality.

Insurance companies advise that flexi hoses are prone to corrosion and degradation from fumes and from contact with household cleaning chemicals stored in the same cupboard (especially chlorine-based products).

Chemicals in enclosed cupboards mainly attack flexihoses through corrosive fumes that concentrate on the stainless braid, eventually causing it to rust, pit, and fail.

🔥 Do not store bleach, toilet cleaner, chlorine sprays or other aggressive cleaners in the same closed cupboard as flexihoses, especially under sinks and vanities.

🔥 If chemicals must be nearby, keep containers sealed, wipe up spills immediately, and avoid creating a “fume cupboard” (an enclosed, humid cabinet full of vapours).

🔥 When cleaning, avoid spraying chemicals directly onto exposed hoses (e.g. at toilet cisterns); use mild cleaners and rinse surfaces afterwards.

🔥 Use polyamide‑braided or other non‑metallic braided hoses in high‑risk “chemical cupboard” environments, as they better resist acidic and alkaline cleaners.

Where flexi hoses hide in a typical home

Most homeowners only think of the kitchen sink. But flexi hoses are everywhere. Check these areas:

✅ Under kitchen sinks (mixer taps, filtered water units)

✅ Bathroom vanities (basins, mixers)

✅ Toilets (inlet hoses)

✅ Laundry tubs and mixers

✅ Washing machines

✅ Dishwashers

✅ Fridges with water lines

✅ Instant boiling / chilled taps

If you rent your home out, this list matters even more. A burst hose during vacancy can ruin floors, cabinetry, and walls.

This bit is uncomfortable. But it’s where people get burned.

DIY work can create hidden risks

Even small DIY plumbing jobs can cause:

❌ Incorrect fittings

❌ Over-tightened threads

❌ Missing sealing washers

❌ Cross-threading

❌ Hoses rubbing on cabinet edges

❌ Poor pressure control

And the scary part? It might not fail today. It fails later. At 2:00 am. When you’re asleep.

Legal Requirements: New Australian Standards from 2025

From 2025, new national plumbing standards under AS/NZS 3500.4 – 2025 Clause 10.10 and AS/NZS 3500.1 – 2025 Clause 5.4.2 introduce stricter legal requirements for isolating valves. Specifically:

🔧Clause 10.10.2 (j) mandates that an isolating valve must be installed immediately before each flexible hose assembly connected to a mixer valve or tap outlet.

🔧 Clause 5.4.2 (l) states that isolating valves shall be installed immediately before each flexible hose assembly connected to a mixer valve, tap outlet or cistern.

This means:

✅All flexihoses installed or replaced must be connected to a compliant, easily accessible isolation valve.

❌Non-compliance may result in insurance rejections, fines during inspections, and potentially serious legal consequences.

❌Not adhering to these sensible standard updates means you are breaking the law in Queensland.

At Whywait Plumbing, we ensure every flexihose installation fully complies with these updated standards and is fully AS/NZS 3500 compliant and future-proof.

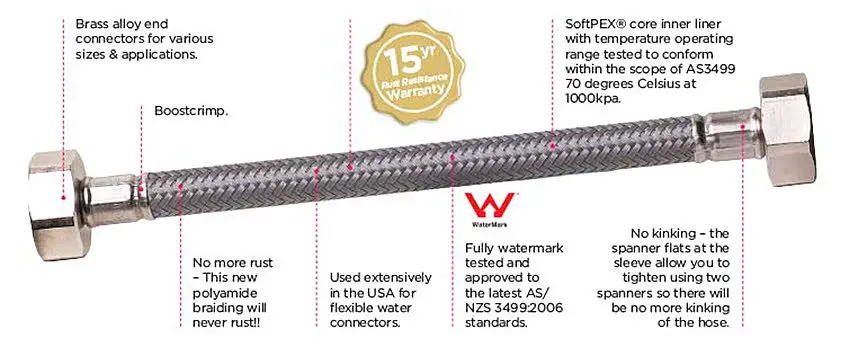

The Solution: Polyamide Flexible Connectors

At Whywait Plumbing, we recommend a reliable, future-proof alternative: Polyamide Flexible Connectors.

Unlike traditional stainless-steel braided hoses, these use non-metallic, corrosion-proof polyamide. The same material in bulletproof vests.

Key Features:

💪 Outstanding corrosion resistance

🛡 Backed by a 15-year rust resistance warranty

✅ WaterMark certified

🔧 Flexible, easy to install

💥 Engineered for higher-pressure use

🔄 Features advanced SOFTPEX® core for added strength and flexibility

Switching to these flexihoses drastically reduces the risk of burst failures in the future.

Replacement rules and best practice (what we actually do)

Flexi hose replacement is not just “swap it over”. Done poorly, it can leak immediately or fail later. Our standard approach:

✅ Isolate water properly (and confirm isolation)

✅ Inspect the fittings, threads, and seat condition

✅ Replace hoses with quality, correctly rated parts

✅ Install without twist, kink, or tension

✅ Confirm correct alignment and support

✅ Test operating pressure

✅ Check for water hammer and pressure spikes

✅ Document findings and recommendations

If we find pressure issues, we’ll recommend the fix. Often, that’s a PRV; sometimes, it’s more.

Our recommended flood-prevention plan (simple, sensible)

If you want the lowest-risk approach, do this:

✅ Identify every flexi hose in the property

✅ Replace any hose older than 5–10 years (or unknown age)

✅ Measure water pressure at the right points

✅ Limit pressure if it’s over 500 kPa (often a PRV solution)

✅ Re-check annually (quick visual check + pressure symptoms)

This is boring maintenance. But it avoids heartbreaking damage.

We’ve seen the aftermath. Swollen cabinetry. Floating floors buckled. That damp smell that lingers.

It’s awful. And it’s preventable. Mostly.

Book a flexible hose safety check

If you want confidence, we can help. We will:

✅ Inspect all visible flexi hoses

✅ Check fittings and stress points

✅ Assess pressure risks and symptoms

✅ Recommend replacements and pressure limiting if needed

✅ Leave you with clear next steps

Don’t wait for the “one day it burst” story.

That story is expensive. And it spreads fast, like water across floating floors.

Insurance fine print example (pressure + compliance)

Most insurers cover sudden water damage. But policies often include conditions and exclusions. Some are buried.

If you’re thinking, ‘surely insurance covers it,’ read this next bit carefully.

You only notice them when you’re already cleaning up a mess. That’s the sting.

If a claim investigation finds the plumbing was non-compliant, or water pressure should have been limited and wasn’t, an insurer can reduce or deny the payout.

That’s not a guarantee either way. But it happens. More than people expect.

The clause insurers often lean on

It’s usually a version of a “reasonable care/maintenance/compliance with law” condition.

It’s often worded so the insurer can argue you didn’t meet your obligations.

Not because they’re “evil”, necessarily. Because it’s the contract, and contracts can be… cold.

Common wording patterns you’ll often see

These are examples of common patterns, not exact wording from any one policy:

📃 A “reasonable care” condition: Requiring you to take reasonable steps to prevent loss or damage. This can include keeping plumbing and fixtures in good order and fixing known defects promptly.

📃 A “maintenance / wear and tear” or “defects” exclusion: Excluding damage that arises from gradual deterioration, lack of maintenance, or existing defects. In practice, they may argue this includes known high pressure, old flexi hoses, or visible corrosion.

📃 A “compliance with laws and regulations” condition: Saying cover may be reduced or refused if the building, systems, or work do not comply with applicable building codes, plumbing rules, or manufacturer installation instructions.

What happens in real claims

When insurers find non-compliant plumbing, unregulated high pressure, or ignored warnings (like corroded flexi hoses, bulges, weeping joints, or no pressure limiting valve where required), they often rely on a combination of:

📃 the “reasonable care” condition, and

📃 a “maintenance / wear and tear / defect” exclusion

That combination can be enough to justify reducing or declining a payout.

And yep, people feel blindsided. Because they thought, “It’s insured.” Then it’s suddenly… complicated.

Why we approach it differently

So we don’t just replace hoses. We check pressure, confirm the setup, and leave you with clarity.

If you want to understand pressure risk properly, read:

Water Pressure Gold Coast: Low vs High Pressure Made Clear

Quick note: Always check your own Product Disclosure Statement and ask your insurer if you’re unsure. Policies vary.

❓ Flexihose FAQs – Your Questions Answered

Flexible hoses are a wear item.

If they’re over 5 years old, inspect them now.

If they’re 10+ years old, replacement is usually the safest choice.

No. In Queensland, all plumbing work, including replacing flexihoses, must be done by a licensed plumber. DIY replacements are illegal and could void your home insurance.

Yes. Low-cost hoses, especially non-Watermark-approved ones bought online or from discount retailers, often fail prematurely. With plumbing, you get what you pay for.

Common culprits include chlorine-based cleaning products stored in humid areas, poor water quality, and proximity to heat. These conditions lead to corrosion that weakens the hose internally.

Look for rust, fraying, bulges, or moisture under sinks. Book a professional inspection if your hose is older than five years or you’re unsure of its condition.

Yes. A documented inspection or audit shows that you’ve taken proactive steps to maintain your plumbing system, which can be crucial if you ever need to make an insurance claim.

Yes. High pressure increases stress and accelerates wear.

It can also worsen water hammer and pressure spikes.

A PRV reduces water pressure to safer levels.

It helps protect taps, appliances, toilets, and flexi hoses.

Not always. The braid can look perfect while the core degrades.

Braided stainless steel does not mean bulletproof.

If one is failing due to age, others may be similar age.

Many homeowners choose a full “hose refresh” for peace of mind.

It depends on your policy and the claim assessment.

Some policies include “reasonable care”, maintenance, and compliance conditions.

If an investigation finds non-compliant plumbing, unmanaged high pressure, or ignored warning signs, an insurer may reduce or deny a payout.

Always check your Product Disclosure Statement.

We have a PLUMBER NEAR YOU 24 Hours, 7 Days a week

Servicing Gold Coast, Tweed & Tamborine.

We answer your call 24/7. You won’t get a call centre or an answering service when you call us. Speak to a plumber 24/7.

Posted onTrustindex verifies that the original source of the review is Google. We couldn’t have been happier, prompt service and great advice . I can highly recommend them !Posted onTrustindex verifies that the original source of the review is Google. From the initial contact to the plumbers getting out on site the whole process to fix a leak on the propoerty side of the water meter was A plus. Gary was brilliant in answering the multitude of questions via email I sent before we got the visit locked in. Lachy and Ben arrived on site exactly when we were told they would and identified the location of the leak and had it fixed super fast. They even answered questions for me about other works I wanted done to the house so will be reaching out again in the very near future to get the guttering on the whole house replaced. Highly recommend the team!Posted onTrustindex verifies that the original source of the review is Google. It is a nice change to deal with a trade group that charges fairly, turns up when they’re supposed to and provides good advice and high quality workmanship. We had a new filter tap, replacement Insinkerator and replacement gas cooktop supplied and installed and we're very happy with the products and the installation. I would have no hesitation in recommending Whywait for your plumbing/gas fitting requirements.Posted onTrustindex verifies that the original source of the review is Google. I cannot fault the service provided by Gary from Whywait Plumbing Services. He responded early on a Sunday morning to an urgent request to fix a broken tap (which turned out to be quite a complicated repair job) and worked on it until it was completely fixed. I'm extremely grateful for Gary's professionalism and expertise and wouldn't consider calling anyone else. Thank you, Gary!!Posted onTrustindex verifies that the original source of the review is Google. Good friendly service, did a great job thanksPosted onTrustindex verifies that the original source of the review is Google. Gary from Why Wait Plumbing completed my Water Efficiency Certificate. From the booking to the completion of the service I was very happy with everything that was provided. I was kept up to date via email and phone. And have them booked out again at our new home to install fridge plumbing. I would not hesitate in referring Why Wait Plumbing. Gary was so friendly and efficient! Thanks Again! And see you next week! ✌🏽

Queensland QBCC Plumbing Licence 78167

New South Wales DFT Plumbing Licence 226900C